Are you going to do the stair renovation yourself? Here are a few more tips for even better results

Are you planning to renovate your stairs yourself? Then here are a few useful tips to make the result even better.

Tip 1: Make a mold from cardboard

A stair spider is not necessary to cut the steps to size. You can also make a mold from cardboard. Cut strips of cardboard the length and width of the steps. Stick these strips together with tape and cut recesses for the stair spindle if necessary. This way you have a 1:1 template that you can use to cut out the transfer steps.

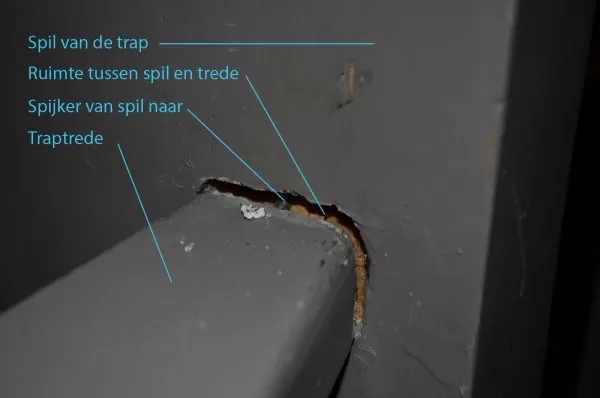

Tip 2: Fill the cracks with sealant

Before installing the transfer steps, it is important to thoroughly clean and vacuum the gaps between the steps and the stair stringers and bars and fill them with flexible sealant. This prevents dirt and moisture from getting into the cracks, which can lead to your stairs creaking when walking up and down.

Tip 3: Make sure there is enough space on the sides

Do not cut the transfer steps too tightly. Leave 2mm space on the sides to allow the transfer steps to expand and contract. If you cut too tightly, this can also cause cracking noises.

Tip 4: Saw away an edge of the existing stair step

When you place the new transfer step, you will notice that the front of the sloping stair steps extends beyond the stair stringer (side). This looks ugly and you are looking at an open edge. By sawing off an edge (approximately 1.5 cm) from each step with the jigsaw, the new transfer step falls within the side.

Tip 5: Apply anti-slip strips

If you purchased transfer steps without anti-slip, it is advisable to apply anti-slip strips, because a new transfer step can be very slippery. These strips ensure that you do not slip on the stairs.

About anti-slip strips

There are two types of anti-slip strips: milling strips and adhesive strips. Milling strips are milled into the stair tread, adhesive strips are glued to the stair tread.

Adhesive strips are better suited for transfer steps

Adhesive strips are better suited for transfer steps than milled strips. Transfer steps are usually not as thick as solid stair steps. Milling strips are often 8 mm high, leaving insufficient material as thickness. This makes the transfer step vulnerable to breaking when walked on.

Compare the qualities of anti-slip strips

There are different types of anti-slip strips on the market. The quality and price of the strips vary widely. When purchasing anti-slip strips, pay attention to the following:

- The thickness of the strip. A thicker strip is more wear-resistant.

- The material of the strip. A PVC strip is more wear-resistant than a sandpaper strip.

- The adhesive layer. The adhesive layer must be strong and adhere well to the stair tread.

Request a color card

If you want to assess the quality of anti-slip strips or choose a good matching color, you can request a color card. If you want to know more about different types of anti-slip products with prices and qualities, read anti-slip strip prices and qualities.

Others enjoyed reading these blogs:

- Painting your stairs as a renovating project

- Create an industrial look for your stairs

- Paint your stairs in a concrete look

Blog writer: Dennis

Comments

Login to give reaction Your comment will be posted as soon as it is approved.