Do you want the very best solution for a non-slip strip in your stairs? Installing a milling strip is then a very good and sustainable choice.

If the stair factory makes the stairs, the customer can opt for a milled anti-slip strip in the steps as an option. Fortunately, this is much more common nowadays, but in earlier years the stairs had to be kept as cheap as possible.

Why is anti-slip not standard in every staircase?

The contractor did not want to pay all those extras for this and therefore the stairs were delivered without these anti-slip slots, the wood had to be cheap because the stairs had to be installed quickly during construction so that the builders could use the stairs instead of a ladder. You understand why the cheapest wood was used, namely spruce.

Nowadays, a steel or aluminum emergency staircase is often installed and the official staircase is only added after most of the work has been done, such as the floors, ceilings and walls.

How to make a milling strip in your stairs

But coming back to the anti-slip milling strip, if you have a house for sale, it is worth considering applying this. If you are not that handy, have this done, there are specialists who do this every day with a nice result. It is not cheap, but it is a sustainable solution with a number of advantages.

Such as: the strip is easy to change after being worn out, unlike a narrow strip that you can stick, this milling strip does not shift and the strip can be mounted nicely and straight, something that is also more difficult with a narrow adhesive strip.

If you have a rental house, it is better to opt for an adhesive anti-slip, which is also easy to remove without much damage to your stairs. Which is a big advantage if you are moving.

If you are a do-it-yourselfer, this job is easy to do.

You are handy, then you can do this job yourself. For this you only need a good router and a straight ruler along which you can run the router.

There are 3 ways how you can do this

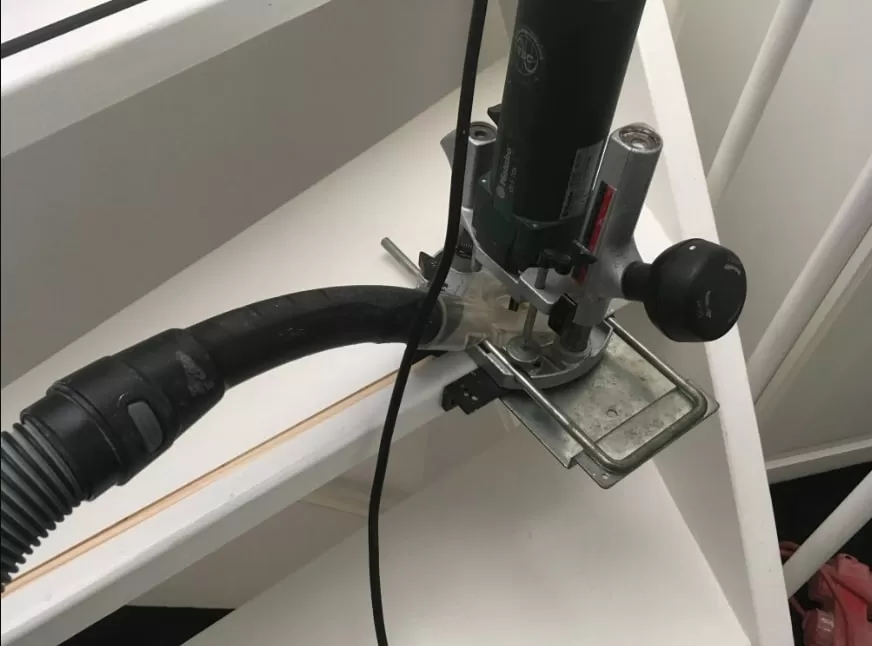

1. A good router is a Makita edge router, it is handy small and you can reach far into the corners with it. In the main photo you can see an example of an edging cutter

You can then simply mill with the guide mounted on it. Mill the groove in depth in 2 or three steps. If you don't have a vacuum cleaner attached to the grinder, ask someone to help you keep a vacuum cleaner nearby because it dusts quite a bit.

Vacuum the groove with every step so that your cutter does not burn. A 7 mm HSS cutter works best. Make sure that you push the cutter and do not pull it, otherwise you run the risk of walking out of the wood. with your milling machine.

2. Milling using a jig, for this you make a jig that determines the width and thickness of the groove. You can use a larger router and on the router you put a freewheel ring that runs through the mold slot. Then almost nothing can go wrong.

How can you make this mold? look on you tube there are different ways and is really not difficult. You can easily clamp the mold with a pair of glue clamps, or a few screws.

3. It is also possible with an ordinary milling cutter, only you then have to remove the guide and let the milling cutter run along a straight ruler. You screw this guide from above with 3 screws, so that it cannot move.

Keep in mind that you cannot get all the way into the corner with a router, so first check which steps will be the shortest and then adjust the length of the anti-slip groove to this, the best thing is if you give them all the same distance from the side .

Here too, it is worth milling in small steps in terms of depth and pushing and not pulling the cutter, always try a test board for the result. The stair strip is usually approximately 2.5 cm from the front of the stair step, and for a residential staircase a single strip is sufficient. Once you have made all the slots, the next step is to paint the stairs.

If you are going to do this job too, read my blog about painting a staircase and how you can best approach this. Sealing the cracks and seams with a flexible sealant is especially important.

Good luck with this winter job!

Dennis

If you have any questions about this, I'll be happy to answer them for you. You just have to create an account because of spam ;-)

Comments

Login to give reaction Your comment will be posted as soon as it is approved.